3D printing with a purpose – our journey

What started with a driven entrepreneur’s passion for creation has grown into a company pushing the limits of 3D printing. From building the first printer in a basement to developing industry-changing solutions.

Along the way, we’ve tackled high-speed printing, medical applications, digital manufacturing, and sustainable production—always driven by the idea that 3D printing should be more than a tool; it should inspire us to re-think and change production and designs.

Explore our milestones below and see how we’ve shaped the future of additive manufacturing, one breakthrough at a time.

"Engineers today are educated to design so stuff fits in transportation units. What will happen when creativity is truly released and organic shapes reenter design? That is the potential 3D printing carries."

2024

Manufacturing solutions take center stage

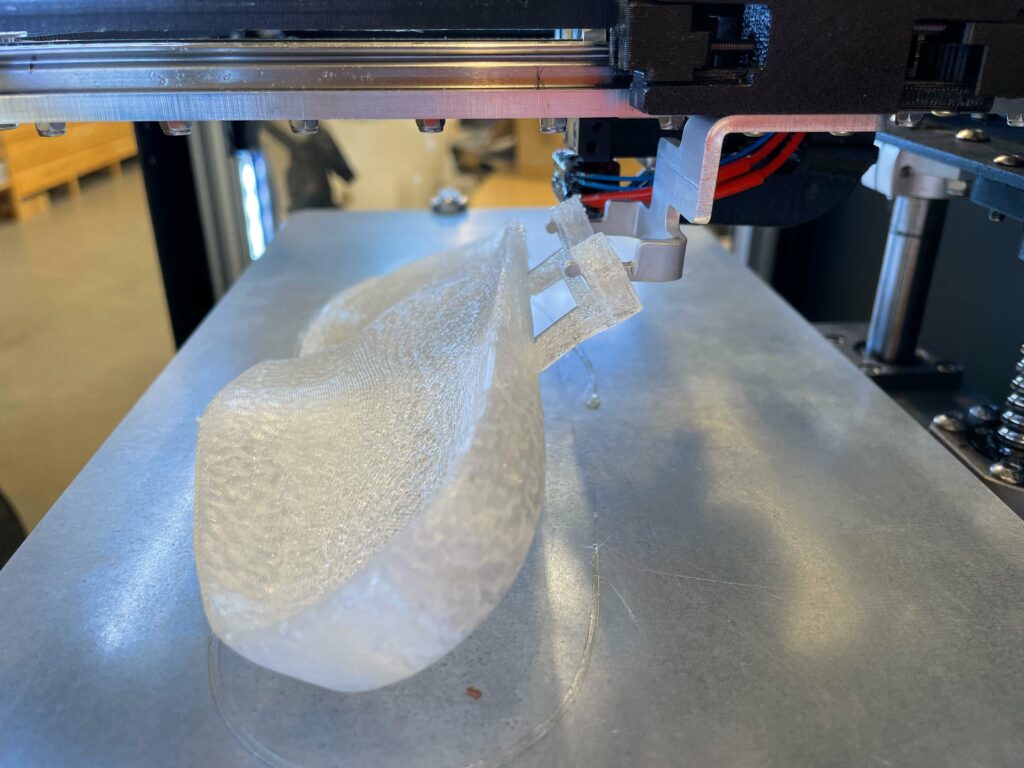

Our journey has always been about making 3D printing more than just a tool—it’s a way to change industries. This year, we launched our seat and corset solutions as a full-scale manufacturing solution and introduced automatic extraction in InsoleMaker, making workflows even smoother. We also registered the Programmable FoamⓇ technology.

2023

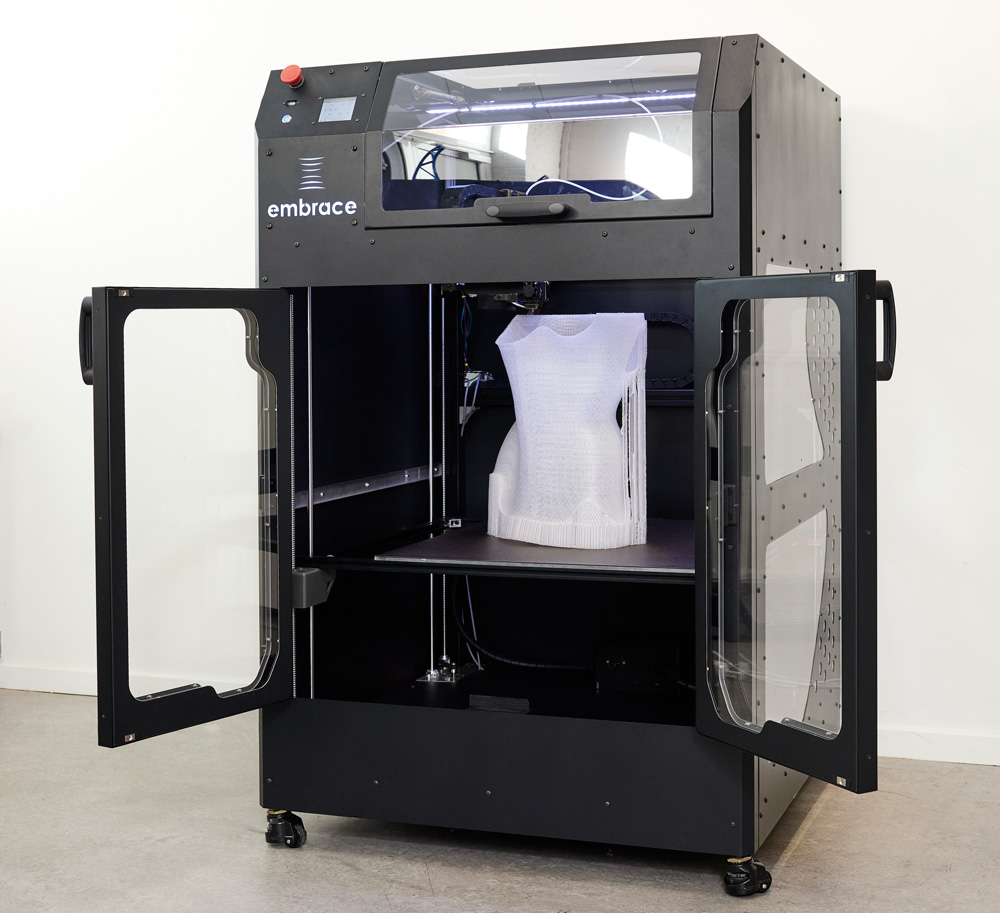

Expanding possibilities in orthotics and prosthetics

We pushed the boundaries of what’s possible in O&P, expanding into 3D-printed corsets and seats for patients. At the same time, we partnered with Meltio to bring our expertise into a white-labeled slicer for metal printing.

2022

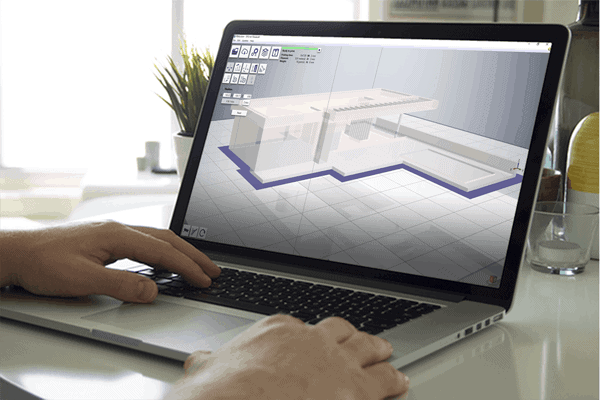

More tools, more impact

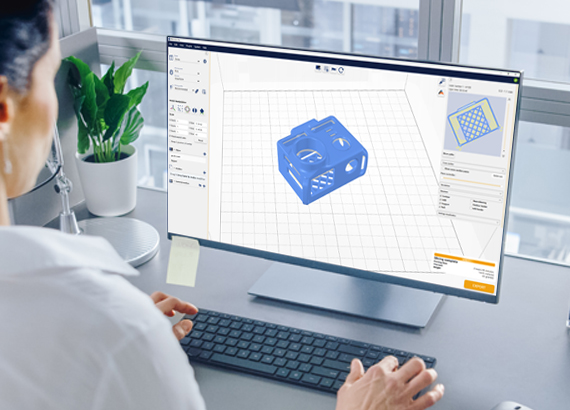

We launched REALvision Pro as a standalone desktop slicer, bringing flexibility to even more users. Meanwhile, the second-generation InsoleMaker took insole customization to the next level.

2021

A new chapter begins

With Jacob M. Nissen stepping in as CEO, we strengthened our vision of making advanced 3D printing more accessible. We also launched our partnership with GebioM, bringing digital manufacturing to foot orthotics, with a dedicated 3D printer and integrated CAD-CAM solution.

2020

Breaking barriers with funding and innovation

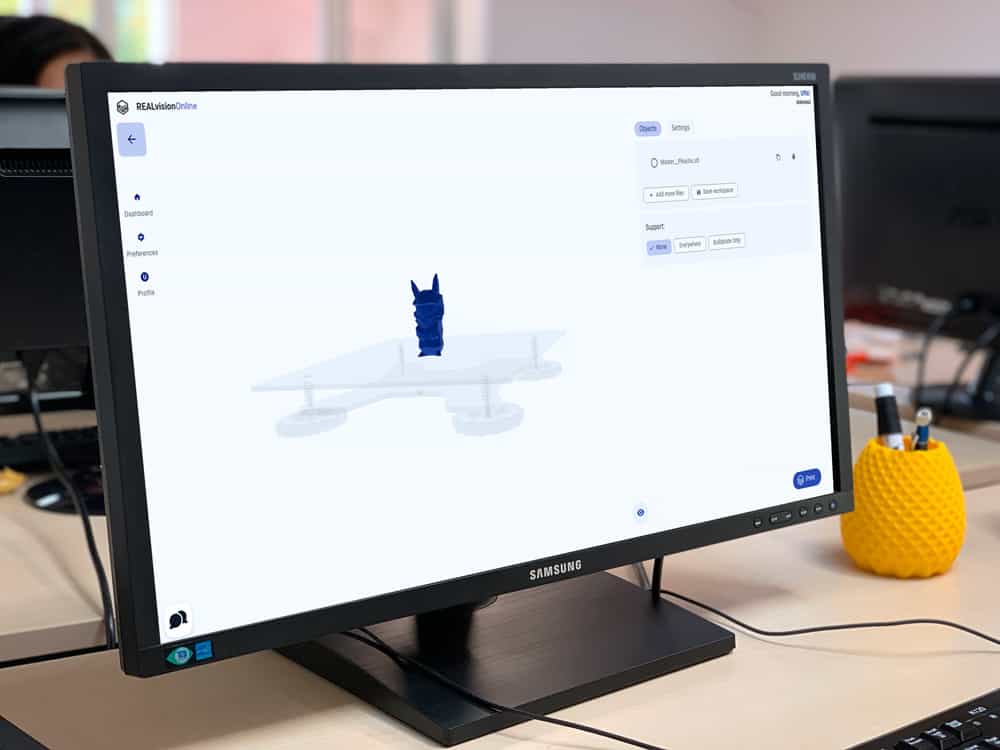

We secured €3.1M in funding with support from Investo Capital and Vækstfonden, giving us the fuel to grow. That same year, we launched REALvision Online, making slicing as easy as browsing a website.

2019

From education to construction

We enabled high-speed 3D printing scaled up for education, making intuitive solutions available to students and teachers. This ensured that students could finish a print within a 45 minutes class

We took 3D printing to construction, printing a house in just hours!

2018

Printing food & fueling growth

We used our technology to 3D print easy-to-eat food for patients with swallowing difficulties.

A €1.3M investment pushed us to refine our technology, making printing faster, easier, and more secure.

2017

A new frontier: medical applications

We took 3D printing into the medical field, printing realistic organ models in silicone for students and professionals to practice.

2014-2017

Pushing the limits of 3D printing

Building everything from scratch meant we were constantly improving. We printed fast, and we implemented secure printing features that enabled our customers to protect their IP, while enhancing 3D printing precision and capabilities.

2014

A breakthrough moment

We launched our first 3D printing electronics and slicing software at TCT in England. The crowd was amazed by the speed—this was the first step in elevating 3D printing to a new level.

2013

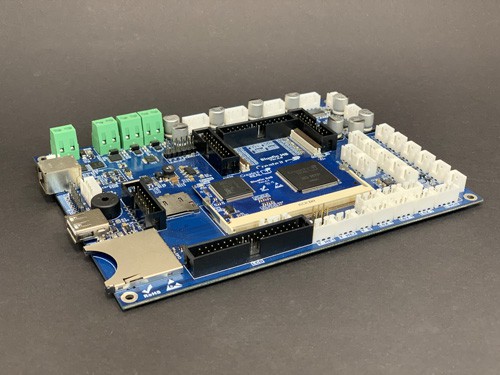

Making 3D printers faster

We developed the world’s first real-time processor for 3D printers, setting new standards for speed.

2012

Experimenting and innovating

Our first control board prototype was made! It was a bit bulky—but it gave us the foundation to test and refine our ideas.

2009

A basement, a dream, and a 3D printer

It all started with Jeremie Gay, a curious engineer who dreamed of making things as easily as he had when he was a kid. Frustrated with slow prototyping in electronics, he built his 3D printer in his basement—the beginning of Create it REAL.