3D-printed correction braces introduced in New York

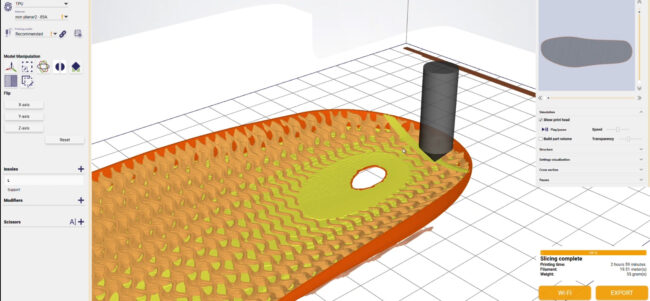

Prothotic Laboratories introduces revolutionary 3D-printed scoliosis braces to the U.S. market First Facility in the U.S. to Integrate the Embrace Corset Solution into Pediatric Orthotics: Prothotic Laboratories, a premier orthotic and prosthetic facility specializing in pediatric care, proudly announces its groundbreaking adoption of 3D printing technology for scoliosis bracing. Located in Farmingdale, NY, and working…