Non-planar printing: Unlocking new potential in 3D printing

Create it REAL is revolutionizing 3D printing with an exciting advancement: non-planar printing. By enabling printers to move in all three dimensions, this technique surpasses traditional 2D stacked layers, delivering enhanced surface quality and unlocking new possibilities for part strength. This is amazing news especially for curved objects that needs a smooth surface.

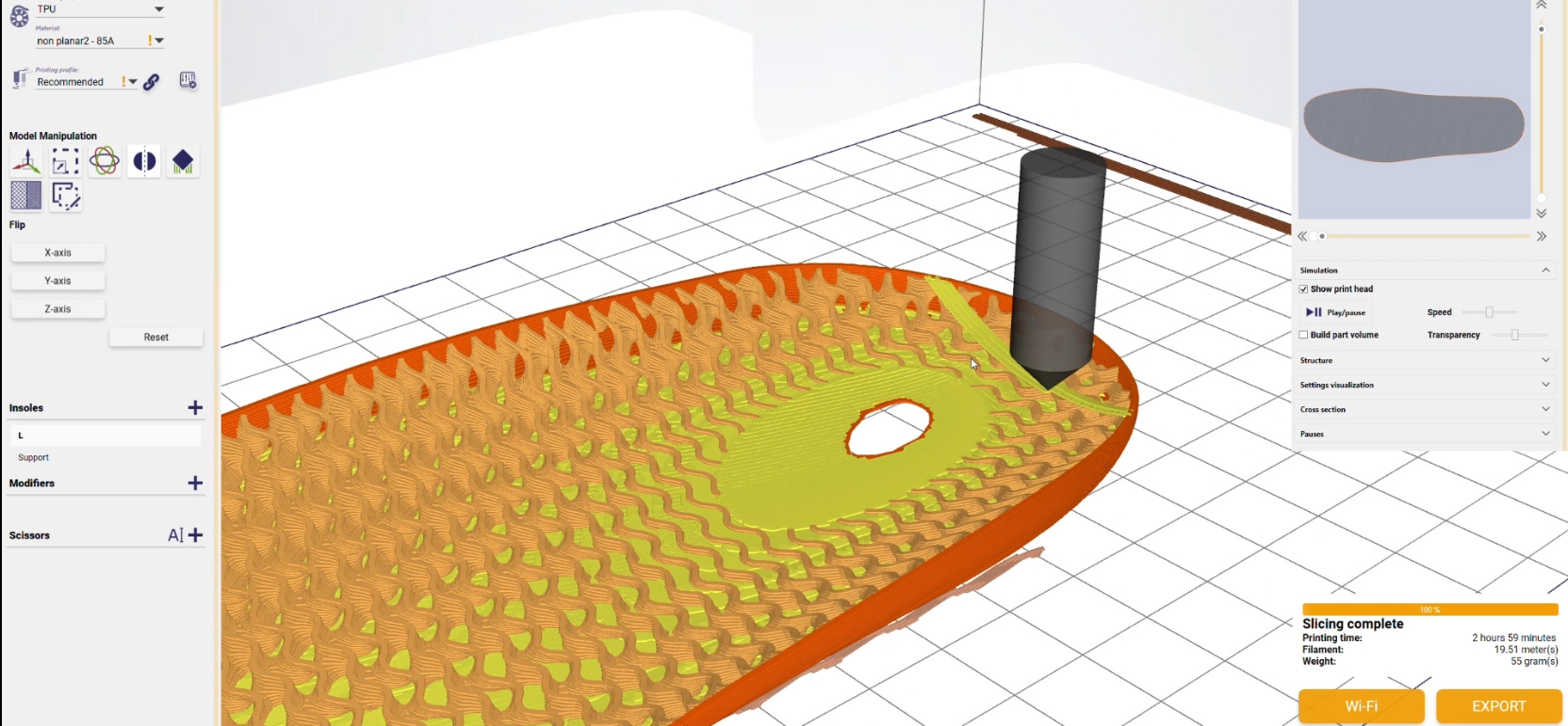

Comfort and finish with non-planar printing

Orthopedic insoles are a key application of this innovation. Non-planar printing is more than just a technical upgrade—it sets a new standard for quality. By precisely wrapping a slicing plane to follow the insole’s curves, the top surface becomes a single, continuous layer. This eliminates the “layer staircase” effect, resulting in a smooth, high-quality finish ideal for products requiring both comfort and precision.

Innovation made simple and user friendly

While this printing technology has been explored before, Create it REAL’s approach is unique. Our slicing engine auto-generates the slicing plane directly from the 3D model, adapting it to your printer’s restrictions and optimization focus—such as surface quality. This makes the technology both powerful and user-friendly.

A unique capability with room to grow

Currently, non-planar printing enhances surface aesthetics, but it also shows promise in improving part strength by tackling inter-layer weaknesses. Looking ahead, we envision optimizing for directional strength, minimizing support structures, and other advanced capabilities—paving the way for even more versatile and efficient additive manufacturing.

With the implementation of the new feature, we’re not just enhancing 3D printing; we’re rethinking it and utilizing all three dimensions to push the boundaries of what’s possible.

The feature is added to the REALvision lineup of unique capabilities available in our solutions. If you are interested in the feature, don’t hesitate to contact us for further details about the release plan.