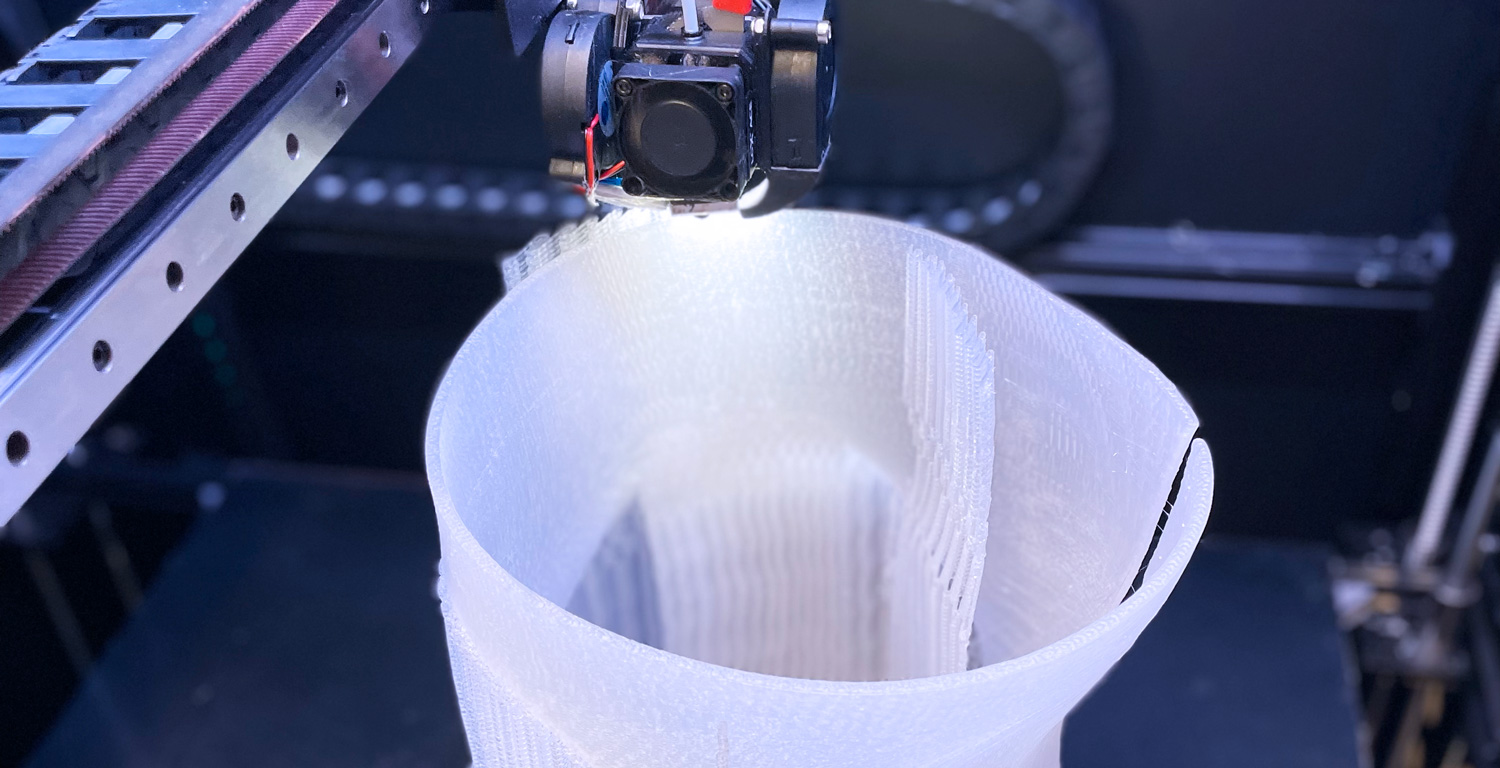

Checking the thickness before printing

Stepping into digital transformation can initially feel overwhelming, which is why we designed our onboarding program. This program is supported by guides, instructional videos, and now enhanced software features. In this story, we will cover the thickness of the walls in the correction brace and how to use best practices for 3D printing.

Our design guidelines recommend a corset wall thickness of 4.5 mm, with a tolerance of +/- 0.5 mm. Deviations from the standard thickness may affect the stiffness and quality in those areas. To monitor this, we have implemented a thickness detection feature in our software.

Thickness Detection feature

We are excited to introduce the thickness detection feature. This feature ensures the correction brace is designed within the design guidelines, ensuring a successful print. Our 3D print service currently uses this feature, and it is straightforward:

- The thickness is detected when a model is loaded into the software. If problems are found, a warning prompt appears, allowing you to investigate the problem areas.

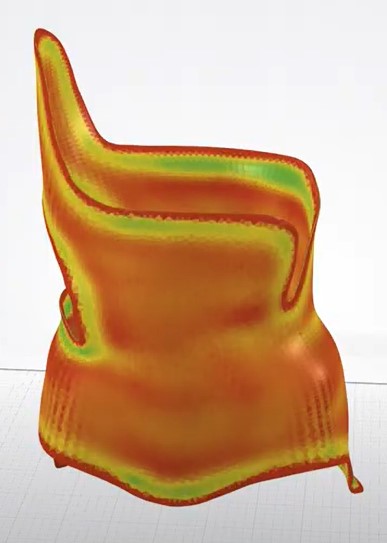

- Get an overview of the areas with issues: We check for 4.5 mm in the 3D model. The internal areas shift to yellow and orange, highlighting thickness issues that must be corrected.

- All green is good to go

- Yellow, orange, and red need to be corrected (printing with risk of failure)

- Return to the CAD design software and make the necessary adjustments.

- If the problem is overlooked, a second warning will appear when slicing.

This feature aims to make it easy and visual for our customers to design the correction brace they want and to allow them to check it before printing.

Providing security

We always welcome feedback from our customers. Typically, our customers have extensive experience traditionally making correction braces. However, for many, 3D printing is relatively new, or their experience is limited. Transitioning to a digital workflow can be disruptive, so focusing on getting the 3D model right is crucial.

Customer feedback on this feature has been positive, with many feeling secure knowing they can correct flaws before printing and avoid failed prints. For our print service experts, it allows them to provide accurate and visual feedback to customers.

This feature is currently used by our print service operators and will be released for general use in Embrace REALvision Corset later this summer.