2020 was a difficult and different year. We all had to deal with COVID-19 social distancing and adapt to this temporary new normal. Thankfully, in our line of business, most of the work can be done through digital technology, so we could keep business as usual.

This is what happened in 2020:

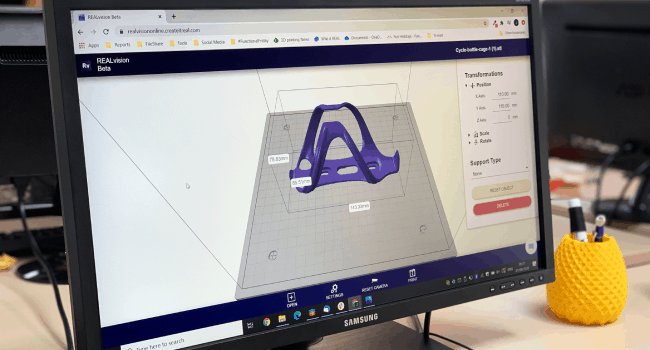

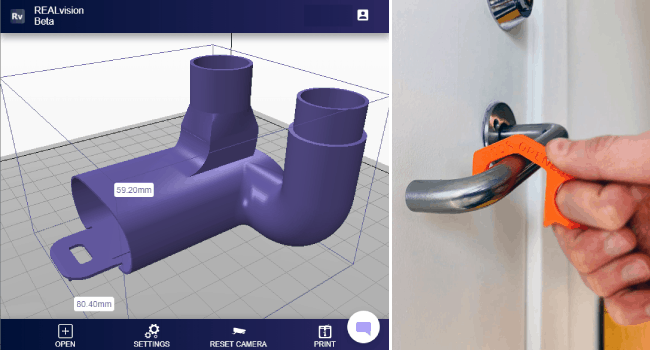

We released REALvision Online, our proprietary online slicer

REALvision Online is a reliable 3D printing online slicing software with a beautiful interface. By moving our slicing to the cloud, we offer you slicing anywhere, and on almost any device. Perfect for educational settings, or in large organizations, we can also customize the solution to your needs. Try it now for free!

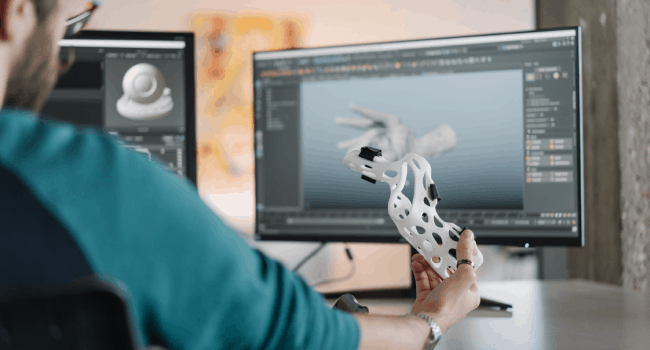

Partnership with Spentys to accelerate the adoption of 3D printing in the orthopedics industry

The goal of this partnership is to develop and validate a 3D printing manufacturing pilot line of limb orthoses, which in the end, is meant to be installed in the orthopaedic provider’s practice. “And that’s precisely why Spentys wants to work closely with orthopaedic providers and offer a local 3D printing solution that will fit seamlessly into the orthopaedic provider’s current patient flow & workflow” Louis-Philippe Broze, co-founder & CEO of Spentys added.

Home office work starts due to COVID-19

Create it REAL starts to work from home. After a dramatic increase in the number of people infected by Coronavirus in Denmark, the Danish Prime Minister Mette Frederiksen has announced the introduction of a few measurements in order to slow down the spread of the virus, including that all non-essential workers work from home. we are still mostly working from home, but our team has been amazing in embracing these changes.

We supported enthusiasts to boost 3D printing productivity worldwide in the fight against COVID-19

Create it REAL has decided to support 3D printing enthusiasts/makers around the world by freely providing Create it REAL high-speed printing technology to anyone 3D printing to fight covid-19. To achieve this, Create it REAL has received extra funding from the Innovation Fund Denmark. They also received backing from their existing investors Vækstfonden Venture (Danish Growth Fund) and 2 private investors.

Modifier feature was introduced in REALvision Pro

Modifiers in the latest version of REALvision allow you to use the geometry of one object to define an area in 3D space that will use different settings for printing

We participated in a REALvision makeover project with Designskolen Kolding

The goal of this project was to bring new perspectives to the table and improve the usability of our slicer – REALvision. In the end we got a functional prototype, user feedback, and tons of design considerations to improve our product! Designskolen Kolding did a great job of implementing the full interaction design cycle with a series of user studies to address the pain points of REALvision and the overall 3D printing process.

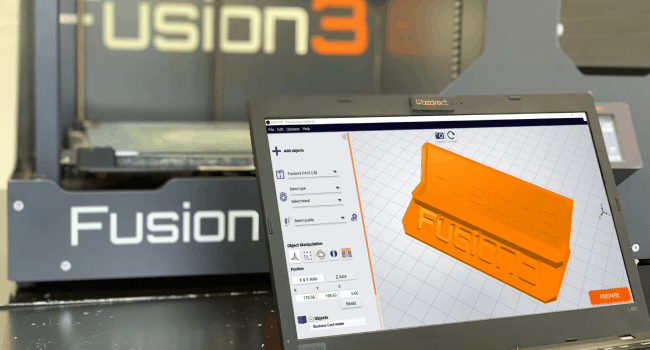

Partnership with Fusion3 on new slicer software REACTOR

Create it REAL and Fusion3 partnered to create “REACTOR”, a slicing software based on the REALvision slicing core, specifically for Fusion3’s professional customer base. REACTOR is Fusion3’s new comprehensive slicing software solution that will provide a streamlined 3D printing experience for their customers. Besides the features found in a traditional slicing software, REACTOR also includes unique features such as modifiers, built-in material list, improved print quality, and planned pause.

We raised 3.1 million euros to accelerate 3D printing market expansion

Create it REAL announces the closing of a EUR 3.1M financing round (DKK 23M). The investment was led by a new investor, Investo Capital, followed by all the existing investors, among these Vækstfonden’s department of direct investments, VF Venture an investment fund helping Danish companies by providing capital and expertise.

We joined a project for fast response capability during health emergencies

The Eur3ka project’s primary objective is to provide global and equal access to a coordinated pandemic emergency response capable of restructuring production capability. For this reason it is important to develop common references, such as manufacturing technologies, and last but not least, the need to build Eur3ka manufacturing networks and capacities across sectors.

These networks and their production capabilities should allow global manufacturing and supply chain functions to be connected, and provided with medical knowledge whenever the need arises. In this way, increased and unexpected demand for medical supplies and equipment will ensure a fast output conversion.

We are excited to see what the next year will bring us!

Want to get the most out of your 3D printer?

Get in touch today to see how Create it REAL’s technology can benefit you.

[vc_btn title=”Contact Us Now” style=”flat” color=”sandy-brown” align=”left” css_el_class=”cir-accent” link=”url:https%3A%2F%2Fwww.createitreal.com%2Fcontact%2F||target:%20_blank|”]