3D printing is transforming the way we innovate. It gives everyone the ability to make their ideas come to life in a matter of hours. But what does 3D printing mean for the manufacturing industry? And how can it reform a company’s business model to stay ahead of the competition?

The Basics of 3D printing

3D printing is building three-dimensional objects from a digital file, one layer at a time. To 3D print, you’ll need a digital 3D model, a slicing software, and a 3D printer. Creating a digital 3D model requires either a 3D modeling software or a 3D scanner. Once the model is ready, it is then exported into an STL file. The slicing software takes this file and splits it into layers and then paths, then generates instructions for the printer.

There are several 3D printing technologies available for different manufacturing applications. If you’d like to know more, Create it REAL can guide you in finding the best solution for your business’ needs.

3D Printing business applications today

Over the years, 3D printing has evolved at an astonishing pace. It now fuels endless innovation within a variety of industries from manufacturing and automotive, to aerospace and medical. The most common application is rapid prototyping. Prototypes can be easily manufactured with more precision and lower costs. It allows engineers to hold their designs in their own hands, making the development process more intuitive and efficient. As 3D printing technologies mature, more and more applications outside of prototypes open up. Companies are now printing functional components and finished products, making production lines more efficient.

The Benefits of 3D Printing for your business

3D printing is a game-changer for prototyping because it allows ideas to be developed, modified, and produced immediately. The ability to fabricate parts, or even finished products, when needed, brings a lot of benefits to any industry.

Improves efficiency and lowers costs

To start with, manufacturing components in-house eliminates the need for bulk purchases and reduces shipping activities and turnaround time. This is particularly important for slow-moving components or hard to ship products. This also means that components printed internally do not bulk your inventory, as they are produced on demand. Hence, less inventory space and costs. Furthermore, localized production minimizes transport costs and allows for on site quality control. 3D printing can also help reduce the need for outsourcing production of components.

Mass customization made easy

In mass customization, moving production closer to the point of use improves your value creation. Highly customized products based on individual specifications involve a lot of challenges around the supply chain. In traditional manufacturing, each product would require unique tools and fixtures. This takes a lot of time and money, especially with complex shapes. With 3D printing and 3D scanning, the customization process can be fully automated from design to production. It lowers turnaround time and improves quality. Highly customized and individualized products also benefit from the flexibility and speed of 3D printing offers.

A great example is the production of a customized orthopedic cast. Create it REAL is working with Spentys, a company that provides complete solution for orthopedic providers to produce customized casts. This allows orthopedic providers to scan, design, and 3D print casts for their patients within their premises. These casts are not only faster to make and cost less but are also more comfortable to wear and are mass customized.

How can we start implementing 3D printing into our company?

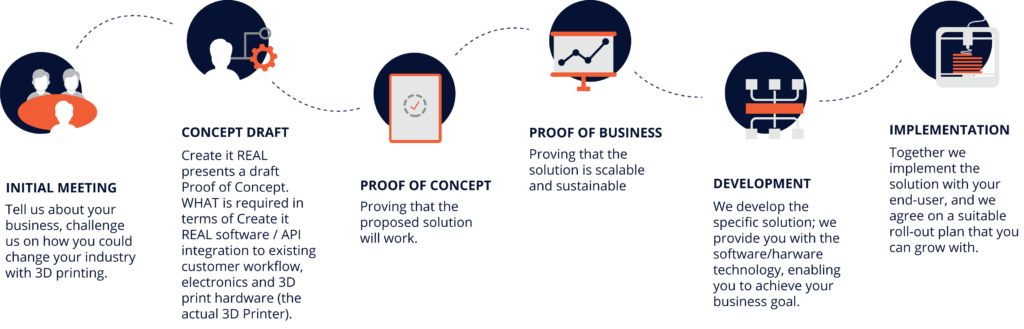

Implementing 3D printing can be challenging because it requires some heavy thinking outside the box. But we’ve said it before, and we’ll say it again; 3D printing is transforming the manufacturing industry. Yet, a lot of companies are lagging behind the competition, as they are uncertain in IF and HOW 3D printing can benefit them.

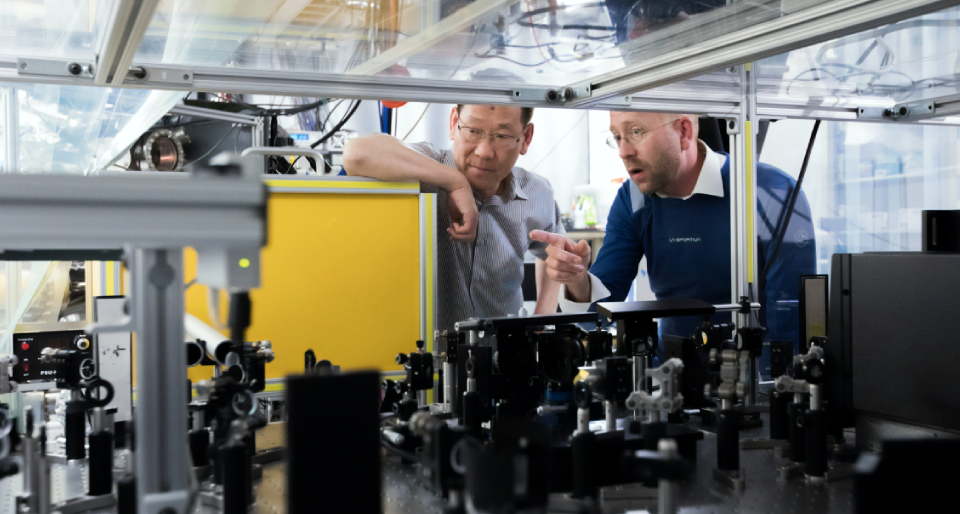

Here at Create it REAL, we don’t just develop high-quality 3D printing electronics and software. We have a proven track record of guiding companies from all sorts of industries to the right 3D printing solutions for their needs. We know the technology and how it works. Most importantly, we understand the needs of different businesses. Thus, we can provide expert guidance on the best 3D printing solution tailored to your needs.

For more information, please contact our team and we’ll be more than happy to assist you.

[vc_btn title=”Contact Us Now” style=”flat” color=”sandy-brown” align=”left” css_animation=”fadeIn” el_class=”cir-accent” link=”url:https%3A%2F%2Fwww.createitreal.com%2Fcontact%2F||target:%20_blank|”]