With the objective of improving the methods of learning and training for students and medical professionals, Inova DE, Create it Real, University of Heidelberg and

The University of Tübingen have started a project to produce realistic and accurate 3D models of a particular patient funded within the framework of the Eurostars Programme.

When medical students learn anatomy, they first learn that the anatomy atlas does not correspond to reality. Each patient differs considerably from what is shown in books and plastic models. The only

reliable study material is actual human bodies donated for medical studies. These bodies are insufficient and access is restricted and in some countries not even available.

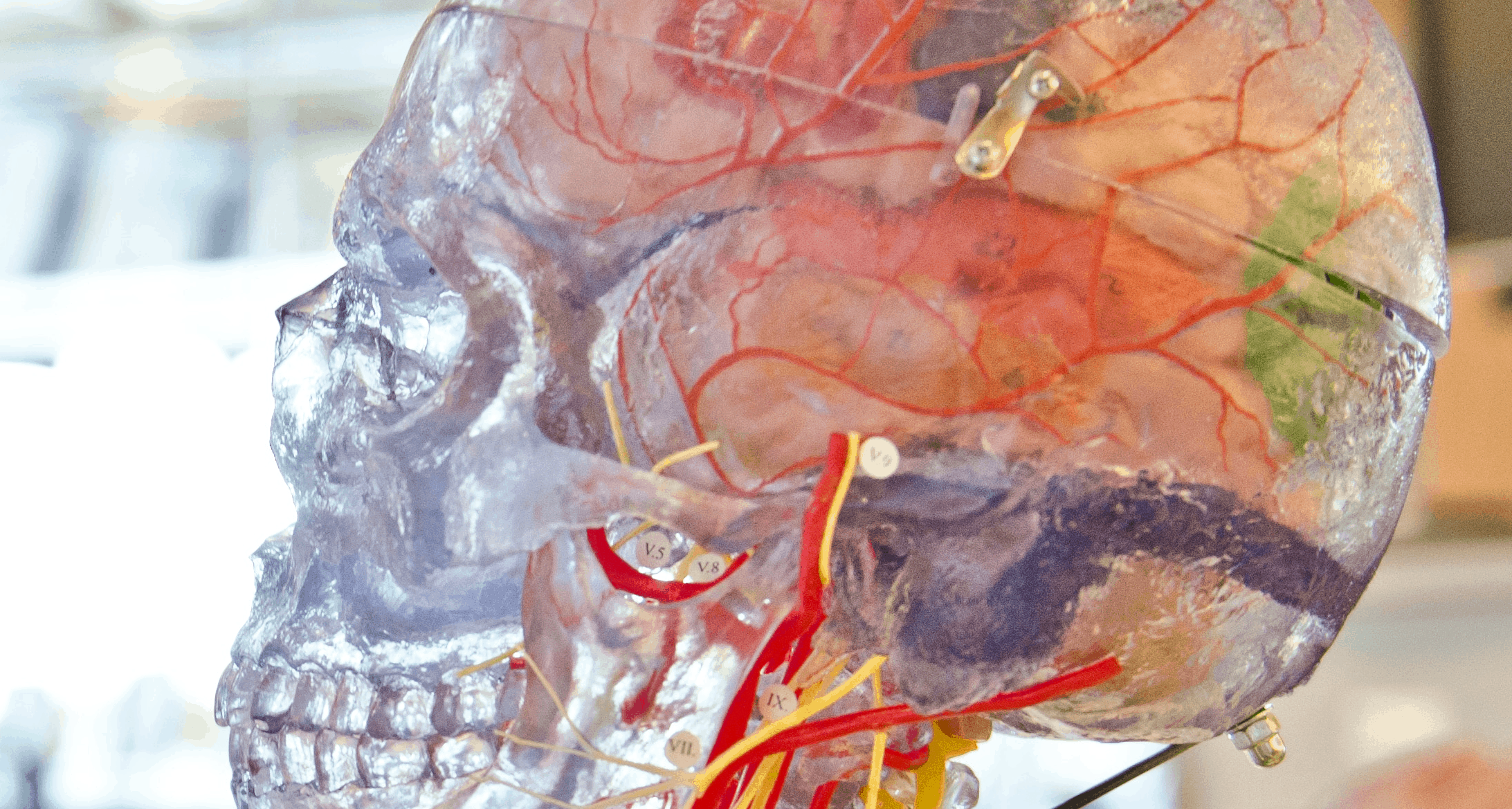

To address this problem, the consortium proposes itself to produce the next level of 3D printing services for medical training and education: 3D printed organ models that are realistic, affordable,

conform to the actual patient images and at the hands of every medical student. These anatomically correct models will have the same haptic characteristics as real organs, enabling a better learning

experience. Real organs have gradual hardness and texture gradients which are not reproducible at an affordable price. With such models, it would be possible to replace animal models that are used today. To make realistic models from patient images the consortium will improve existing hardware and software models available for 3D printing.

The project will run until the end of March 2020.

About the partners:

Inova DE, GmbH is specialized in software development for medical applications and telemedicine services. We pride ourselves of our transversal approach towards the healthcare market. By leveraging the expertise of multiple industry partners, academia and clinical partners we seek to create the products that have a direct reflection of current market needs and trends. Our innovative mindset and scientific expertise is best expressed by our technology integration efforts, scientific programming, development and know-how. We program in multiple languages different types of systems, from treatment planning stations to telemedicine and other on-line based services, as is demonstrated by this and other funded projects we are involved. Our key personnel are trained in the DIN 62304 – Medical device software, ISO 13485 – Quality management and ISO 14971 – Medical Device Risk Management. Beside server-sided development, the User Interface and the specificity of the systems usability are strong core competencies that complement our scientific programming.

Please find further information at www.inova-de.eu.

The University of Heidelberg is the oldest German university, one of the most renowned universities worldwide with a strong life science focus in research and in education. Biomedicine is an important part of the German Universities Excellence Initiative, Heidelberg University being one of nine German universities to meet the criteria for this. True to its mission statement “Scientific Excellence for Your Health” intensive research activities make it possible to implement latest research results in its treatment standards.

Please find further information at https://www.klinikum.uni-heidelberg.de

Surgical Clinic for general, Visceral & Transplant Surgery from the University Clinic Tübingen has been active since 1805 and is one of the leading teaching centre in Germany for Minimally Invasive Surgery and Endoscopy.

The working group “surgical technology and training” in the medical faculty of the University of Tübingen focusses on the development of new surgical instruments and Training models. Besides the development of Trainers that relied on animal specimen they started to create training models by 3D printing for endoscopy and minimal invasive surgical procedures.

Please find further information at https://goo.gl/WsnR9B

Based in Aalborg, the old Danish “Silicon Valley”, the Create It REAL international team is made up of experts in 3D printing technologies, electronics, 3D graphics and mechanics. The team is composed by professionals with a very good understanding of the intellectual property issues and opportunities around the additive manufacturing technology. They have experience in high technology product development and they are well aware of the need for flexible and easy to use solutions. The team works like an R&D centre, developing technology and releasing platform solutions to easily create desktop 3D printer products. Using state of the art technology, they create custom features and provide excellent platform tools to hide the complexity of this advanced technology, while, at the same time, allowing quick integration of the technology into new products and considerably reducing the time to market. They have launched in December 2013 the worldwide first 3D printing Real Time processor that allows 3D printers to reach high speed (up to 5 times faster than current printers). Using its own electronic and own software (slicer and UI), they promote its technology and know-how to 3D printer manufacturers around the world. The company also participates in other EU projects called Nanomaster where they developed Graphene-based filament to allow conductive 3D printing objects.

Nice information! Thanks for this article