Aalborg – June 13th, 2017 – Even though the 3D printing market is booming, many companies or designers creating 3D models are reluctant to share or sell them online because of intellectual property issues. Same as for the music industry back in the 90’s when the mp3 became popular, 3D files could be copied, altered and shared for free on internet. New business models emerged, like with Spotify, and helped the industry to move forward. Create it REAL, the Danish R&D center specialised in 3D printing technologies, has developed a solution that will allow designers to create their new business models.

Based on their unique real-time processor which allows a print speed up to five times faster than standard FDM printers, the chip is now able to decrypt secured files directly in the printer.

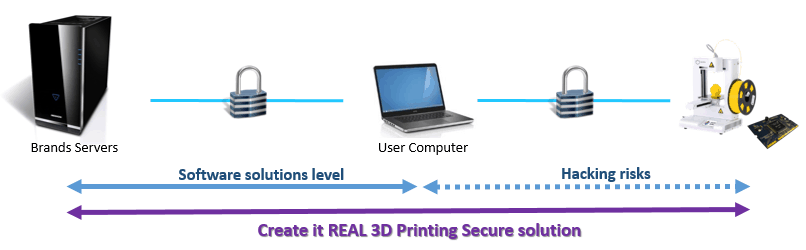

This means that end-users can print 3D objects without the need to access the original file which brings many benefits to all parties such as:

End-users will be sure to get high quality branded files, with guaranteed printability.

No slicer is needed to prepare the files as they will get them ready to be printed.

Nobody can modify the file during the streaming which is key for mechanical parts for example

Brands will finally have an efficient way to value their 3D files in a secured and user-friendly environment. “Our technology opens new opportunities for FDM and SLA 3D printer manufacturers and users” says Jeremie Pierre Gay, CEO of Create it REAL. “Imagine companies able to print or sell spare parts on-demand without the fear of losing their intellectual property. They would make huge savings on storage, transport, obsolescence issues, and could make the parts available forever to their customers”.

“Our platform can be quickly integrated by 3D printer manufacturers and we are already working with some of them on this project. The market potential is incredible as we aim to fix one of the biggest challenges in the 3D printing industry right now. Like in the music or video industry, there will always be pirated content or lower-quality copies; however, we still need to help companies to guarantee their customers or partners the best 3D printing experience. Brands are trusted by their customers and must offer high quality and genuine files, 100% safe and tested for their printer and consumables.”

picture

Cults, one of the leading 3D model repository supports the project to bring exclusive and secured content to their customers. Hugo Fromont and Pierre Ayroles, Cults co-founders comment “Many designers on our platform are looking for such innovation so they could sell their work being sure they would not find a copy on internet. We are very happy to join Create it REAL’s as their solution is very promising and will push the market limits”.

“By 2018, 3D printing will result in the loss of at least $100 billion per year in intellectual property loss globally” mentioned Gartner in their top 10 predictions for 2014 and beyond. This project is trying to avoid this catastrophic scenario and develop the 3D file offerings as more companies and freelancers will be confident they will not lose their work. In the end, more files to 3D print will also accelerate the 3D printing market.

Jeremie added “it will take time to build a large 3D printer installed base to attract consumer oriented brands; however, our solution can be quickly implemented for the B2B market. Imagine engineering or consulting companies, buying a set of secured printers to leave at their customer sites to allow them to 3D print their project.

The team has developed several prototypes and is now looking for large scale pilot programs with professional end-users all over the world before releasing the solution by the end of the year. 3D printer manufacturers are also welcome to try the platform and should contact the team for more information.

Create it REAL platform features:

– Up to 5 times faster print speed than standard FDM printers

– Compatible with FDM and SLA 3D printers

– End-to end encryption support to secure designer’s intellectual property

– Augmented reality feature to preview real size projects

– REALvision slicer supports STL and G-code files

– Developed and produced in Denmark