Stay updated and subscribe to our free, bi-monthly newsletter Insight

Best 3D print solutions for Orthotics and Prosthetics

Get ready to scale your business in a clean work environment, reduce waste up to 85%, and gain more time to focus on patient care.

Designed for Orthopedic professionals

Built for performance

Together, we transform your manufacturing process into an innovative, automated, and local production of high-quality and reliable devices. Get started with our End-to-End 3D printing solutions for custom orthopedic cushions, seats, spinal braces, and insoles.

“Our complete solution includes hardware, material, and software – everything you need to start 3D printing orthopedic devices. We enable you to create highly customized orthopedic devices faster, with better fit and comfort – without the complexity.”

– Jeremie Pierre Gay, Founder and CTO

Read about our use cases

Our 3D printing technology offers dedicated solutions for manufacturing within the O&P industry.

All our solutions are developed with the final medical device and the comfort of the end-user in mind.

From digital model to final product - in just a few steps

- Reduce labor time – Manufacture custom orthopedic devices by pressing print.

- Enhance patient comfort – Perfect fit and optimized pressure distribution.

- Streamline your workflow – Seamlessly integrate with existing scanning and design software.

- Scalable & cost-effective – Lower material waste and operational costs.

Programmable Foam® our unique capability

Programmable Foam® offers an innovative alternative to traditional foam, and is a great compliment to many orthopedic devices. Our patent-pending 3D printing technology ensures unmatched performance.

- We enable you to go digital with a streamlined workflow for customized devices.

- Our high-quality 3D-printed foam is breathable, hygienic, and bio-compatible.

- Ensures shock absorption, cushioning and comfort by effectively distributing and relieving pressure.

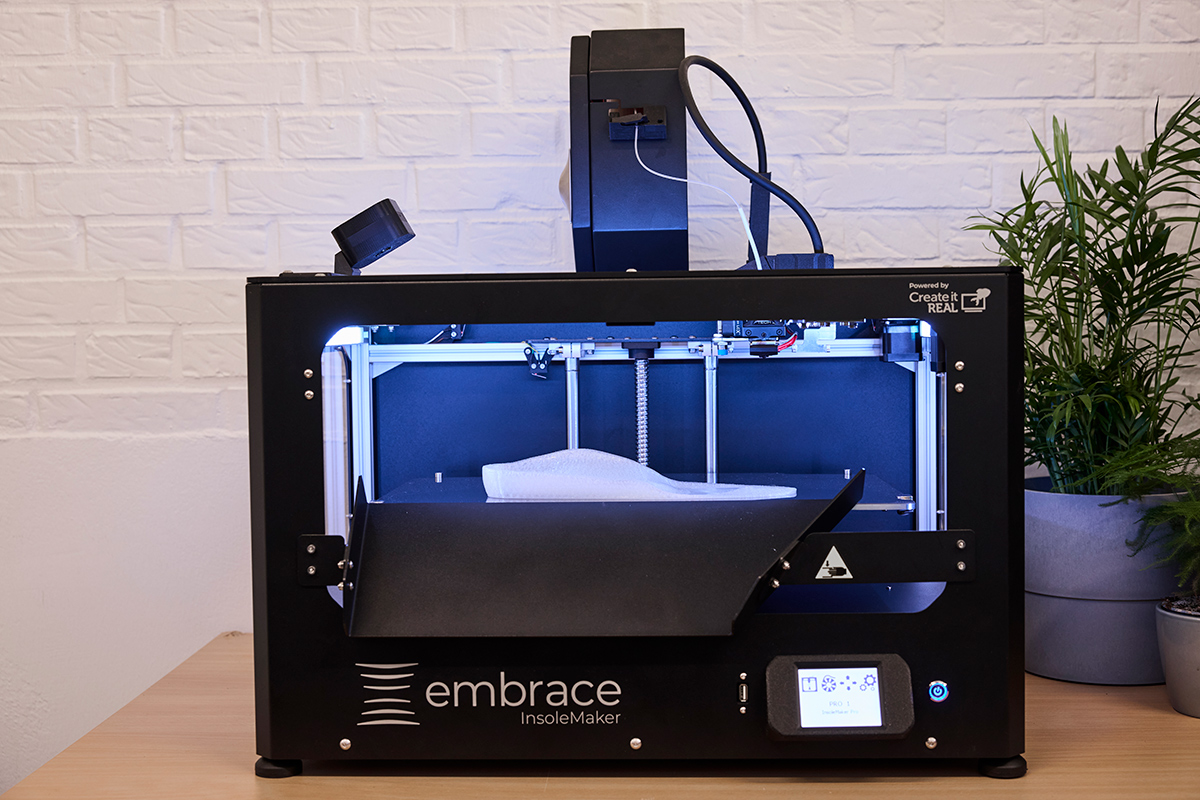

Automatic extraction of insoles

The patent-pending automatic extraction ensures continuous production and faster ROI.

This option seamlessly enhances the Embrace Insole solution, enabling production to continue beyond regular office hours. With this advancement, the custom insole is automatically labeled, detached, and gently guided down a ramp into a designated box. A built-in camera validates the success of the extraction process.

Are you ready to 3D print your orthotics?

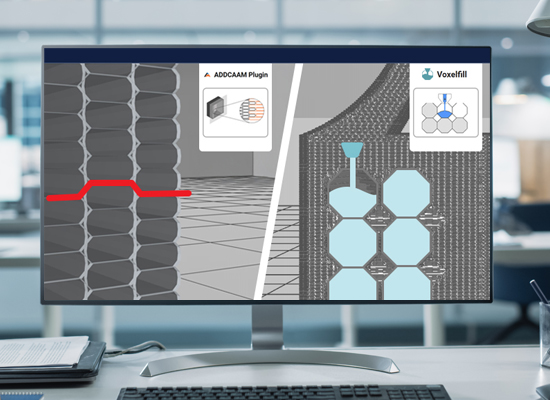

Get stronger 3D prints with REALvision Pro

Design your 3D objects and bring them to life with our standalone slicer software, REALvision Pro, the powerful and user-friendly build preparation tool. Import your CAD designs, visualize them as 3D prints, and achieve superior results with smarter slicing strategies.

With the release of REALvision 5.0, we’re taking 3D printing to the next level. We introduce the ADDCAAM plugin, a multi-patented technology that enhances strength and reduces porosity in FDM printing.

Featuring an improved interface, expanded printer support, and advanced print simulation, REALvision Pro offers you unparalleled control over your printing process.

Get started with digital Orthopedic manufacturing

Additive manufacturing is still young, but more and more businesses are becoming aware that traditional production methods need alternatives. As a business partner, we help you create the right setup for your 3D printing program. We can start with a consultation, or you can order a sample.